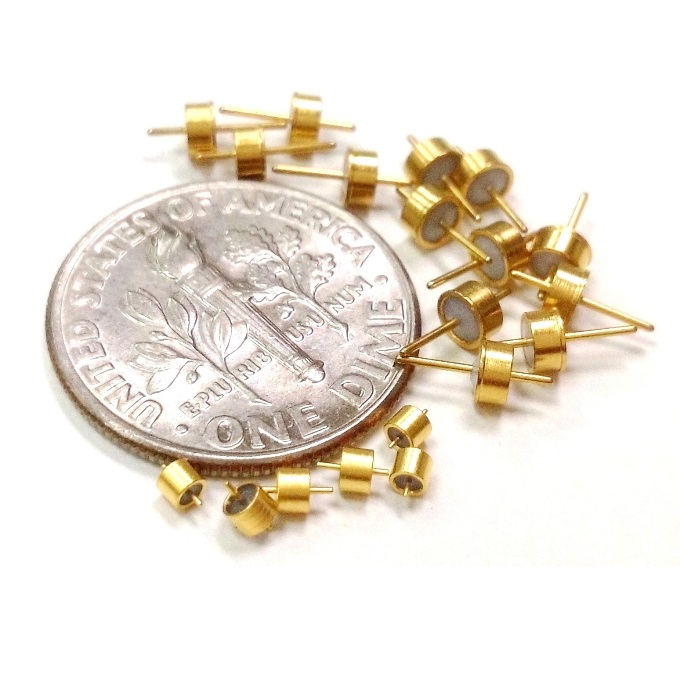

Glass to metal seal

Glass To Metal Seal Manufacturer for hermetic feedthrough.

※ Matching seals

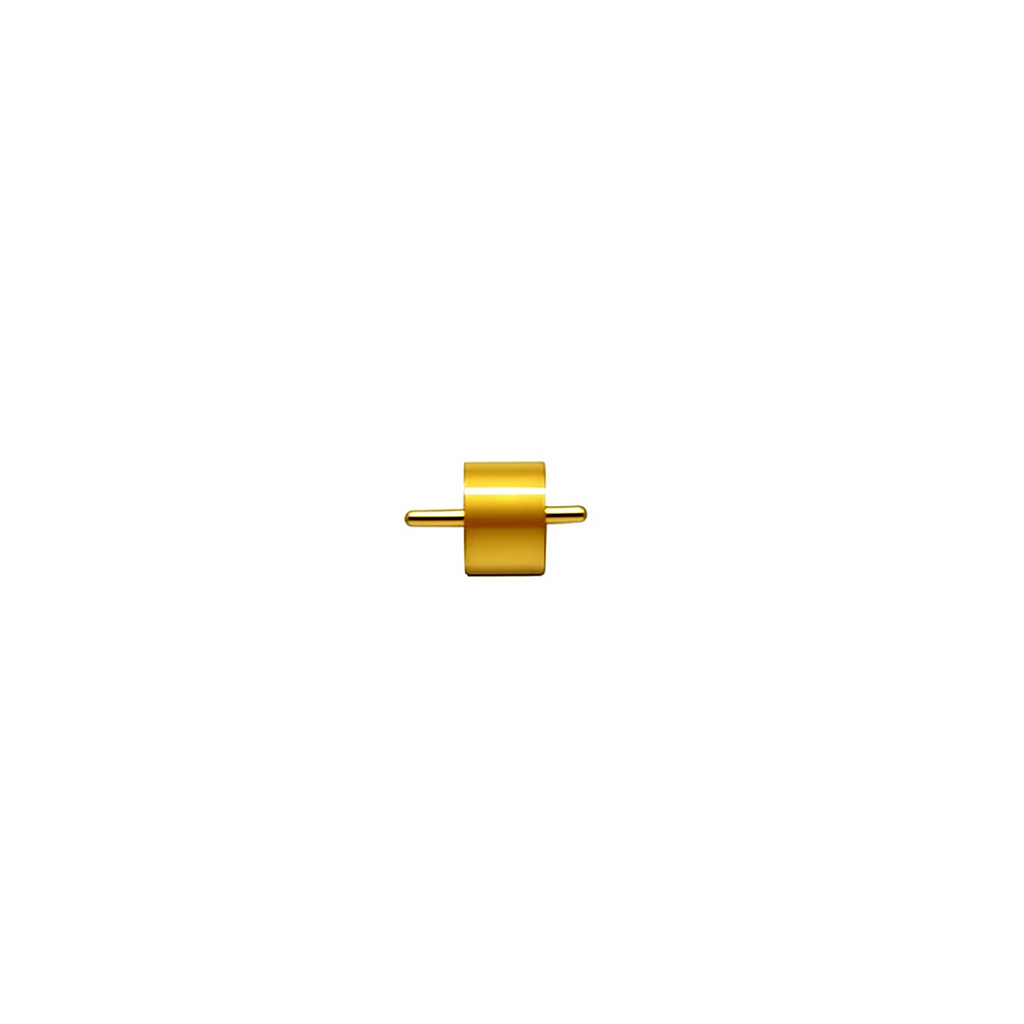

To create a matching seal, the housing and glass materials were chosen to have similar coefficients of thermal expansion. The strength of the matching seal comes primarily from the chemical bonds between the glass and oxides formed on the metal part. Matching seals are usually made of Kovar housing and feet and borosilicate glass.

※ Compression seal

Compressed air-tight seals are made using a housing with a material with a higher thermal expansion rate than glass. After the seal cures during manufacturing, the enclosure will shrink around the glass, applying the desired compressive stress on the glass beads. The strength of the glass-to-metal seal is enhanced both mechanically and chemically, resulting in stronger, more reliable parts. Compression seals are typically made with steel or stainless steel housings, nickel-iron pins, and barium-alkali glass.

※ Application of GTMS

Vacuum components, sensor or transducer housings, continuity for harsh environments, battery connectors and medical implants.

Electrical conduction for various commercial and military applications

RF/Microwave Hybrid or Microcircuit Packaging

Photoelectric element housing

Hermetic encapsulation for the microelectronics industry is a hermetically sealed container for protecting critical microelectronics and components

ZIDE is a leading glass to metal seal manufacturer who has concentrated on continuous improvement in hermetic feedthrough quality.